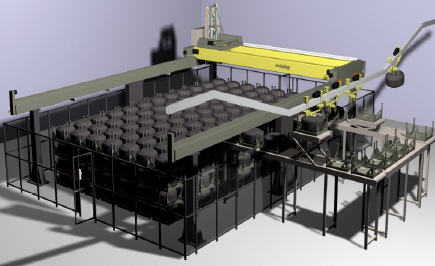

TyrePick-GT, flexible robotic storage for green tires

Green tire storage is an essential part of the

tire manufacturing process in order to balance production fluctuations between

tire building and curing operations.

Cimcorp’s fully automated green tire handling and storing system consists of a

variable number of MBR 800 TyrePick robots with an MP-OPS storage management &

control system, universal tire-pallets and pallet conveyor system.

Each green tire is loaded on the universal tire pallet before being stored in

the floor storage. Pallet loading is carried out automatically either by an

electric monorail system or a separate tire handling manipulator. Tire-pallets

in the storage are stacked one on the other by a TyrePick robot. The robot can

handle 1-2 pallets at a time with a multi-gripper. One tire-stack in the storage

consists of max. 6 pallets. Empty and loaded pallets are stored in the same

dynamic buffer storage. The tires are retrieved from the storage according to

picking orders which follow the curing sequence. Picking is performed according

to FI-FO principle.

The MBR buffer storage system can be applied to different sizes and types of

tires (PCR, UHPT, TBR etc.). The picking and storing strategy is the

first-in/first-out principle. The article selection and number of locations on

the floor are freely-programmable instead of being fixed with stationary

equipment. Data tracking throughout the storage and conveyors is an integrated

part of the control system.

Quality control

Green tires do not touch each other in any phase of the process, nor are they

squeezed flat because each tire is properly supported on the pallet while being

handled, transported and stored in the storage. This kind of handling is

essential to maintain the high quality of green tires.

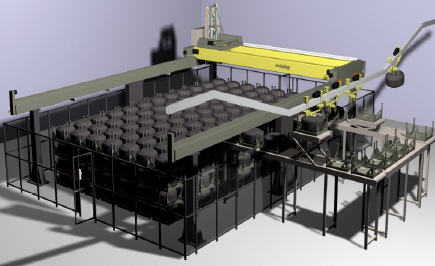

TyrePick-FT, buffer storage and palletizing cell for finished tires

Sorting, buffering and palletizing are essential

operations, which are strongly connected to the automated inspection of finished

tires. Cimcorp’s solution is to perform all these handling tasks with one

flexible fully automated solution. Sorting, stacking, buffering, de-stacking and

palletising functions are all integrated into Cimcorp’s TyrePick concept.

System components

A fully automated buffer storage and palletizing system consists of a variable

number of Cimcorp’s TyrePick robots with an MP-OPS control system. MP-OPS

manages not only the buffer storage, but also the material flow and palletizing

operations within the TyrePick system.

The MBR buffer storage and palletizing system can be applied to different sizes

and types of tires (PCR, UHPT, TBR etc.). The storing and picking strategy

follows the first-in / first-out principle.

The article selection and number of locations on the floor are

freely-programmable instead of being fixed with stationary equipment. To

optimize the floor space, the storage area can be divided into different tire

diameter groups. Each group has an independent storage grid which is

freely-programmable and can be changed according to the daily production

program.

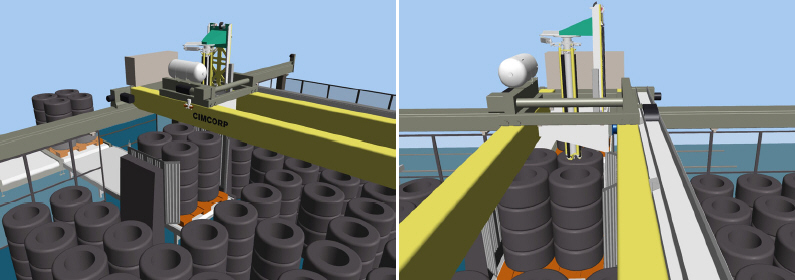

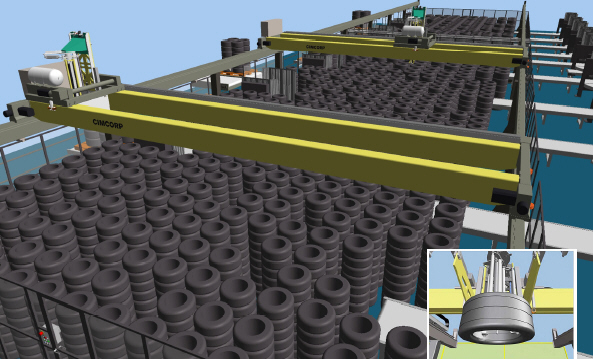

TyrePick-OP, automated order picking system in shipping area

Accurate, flexible and prompt dispatch operations

play a key role in the total distribution chain of tires. Errors in picking and

delays in distribution can cause unexpected extra logistics costs.

Cimcorp’s automated order picking systems have been developed to manage dispatch

operations with high performance and error-free picking. The content of each

delivery route is sent to the floor storage from the warehouse in advance to

guarantee fast and flexible picking operations while delivery vehicles are being

loaded.

System overview

Tire pallets arrive from the warehouse to the selected robot pick-up position

where pallet and tire stacks are centered before the stacks are picked by the

robot. The TyrePick robot picks and allocates the tires to floor storage to wait

for the order picking.

Order picking can be done in reverse sequence to the vehicle’s unloading

sequence at the destination (first in - last out). This is managed by the

storage management and control system MP-OPS. MP-OPS takes care that there are

always enough tires on the floor storage to fulfill incoming picking orders. If

a certain tire type which is needed for incoming orders is running out, MP-OPS

orders replenishments from the main warehouse in quantities of full pallets.

Extra tires in the storage can be returned to the warehouse if they are not used

for future orders.

TyrePick robots are able to pick tires from any location of the floor storage

and to deposit tires onto any out-feed conveyor within the system. Depending on

the order size, a robot can pick any number of tires from the tire stack, from

one single tire up to a full stack.

Cimcorp’s automated order picking system can be applied to different sizes and

types of tires (PCR, UHPT, TBR etc.). The storing and picking strategy is the

first-in first-out principle. The article selection and number of locations on

the floor are freely-programmable rather than fixed with stationary equipment.

Data tracking in the buffer storage and on the conveyors is an integrated part

of the control system.