Korean Air Flight Centre at the cutting

edge

Faster and more reliable service for airlines

Airport kitchens have to serve departing

flights under great time pressure. Besides handling food, drinks,

equipment and goods for sale, catering carts provide kitchens with their

own logistic challenge. After returning from arriving flights, catering

carts must always be emptied, washed, stored and refilled before being

delivered to departing flights again. The Swisslog Group companies Cimcorp

and Schierholz have jointly supplied Korean Air's new airport flight

kitchen at Incheon with an automated catering cart transportation and

buffer system.

|

Korean Air has built an airport kitchen at Seoul's new international Incheon

airport, where catering cart handling and buffering is completely automated.

Swisslog Groupís overhead conveyor supplier Louis Schierholz GmbH of Germany

had already supplied a number of catering facilities worldwide with

transport and buffer systems using conventional technology. Now, Cimcorp and

Schierholz have jointly developed and implemented a new concept for the

transportation and buffering of catering carts using an electric monorail

system (EMS) and a wide span gantry robot (GR). |

Hygiene and speed guaranteed

The core of the buffer system is a large gantry

robot supplied by Cimcorp. The catering carts, after having been stripped

of waste and washed, are stored on hangers in the robot's working area

until they are needed again.

The catering carts arrive in the working area

from the cart wash on hangers moving along the EMS supplied by Schierholz.

The robot picks the hangers and moves them to the buffer for storage from

where they are picked and unloaded according to the orders. A single order

always consists of all the catering carts needed for one flight. Once the

order is received, the robot picks the hangers from the buffer to meet the

order and moves them to the unloading station. From there, the hangers

again travel along the Schierholz EMS to different destinations for

refilling. Catering carts from various airlines are stored in the buffer

and, depending on the type of cart, one hanger can hold from 2 to 4 carts.

The capacity of the buffer totals 450 hangers. In one hour 70 hangers can

be moved in and 70 hangers can be moved out of the buffer. The catering

facility operates 18 hours per day and 351 days per year.

Since the catering carts are stored in hangers

under the gantry robot, no fixed structures are needed on the floor, which

would hinder cleaning. The floor area can easily be cleared and washed

whenever required. Another advantage of the overhead structures is that

the retrieval of the catering carts needed from the buffer happens

quickly. The robot gripper, having direct access, is able to pick hangers

from anywhere in the robot's working area within seconds.

|

Korean Air

eagerly grasped the opportunity to adapt the latest technology for their airport

kitchen. The concept developed by Cimcorp and Schierholz is unique in the

industry. |

Space-saving

Despite its extremely wide span,

the gantry robot as the heart of the buffer reduces the buffer space

requirements considerably compared with conventional solutions. The hangers

with the catering carts can be stored in two layers in the robot's working

area. The robot is equipped with an OPS-Box warehouse management system,

which controls the stock under the gantry robot according to the product

editor and the orders coming from the upper-level software. In

this way, trouble-free and reliable delivery of catering carts is

guaranteed. The software incorporates a storage optimization feature, which

facilitates effective utilization of the available space.

|

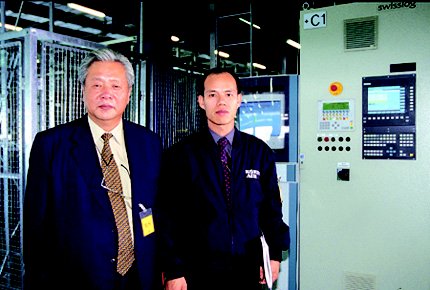

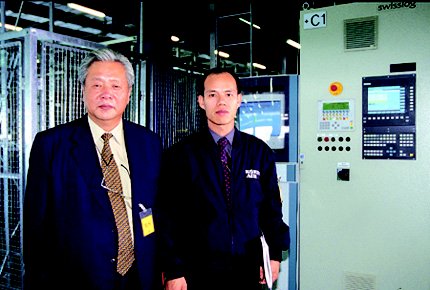

EKL Eastern Korea's Managing Director Alex Kim and the Assistant General Manager

of Korean Air's catering team, Mr. K.H. Kwak, familiarize themselves with the

catering cart buffer, which is ready for commissioning. Mr. Kwak appreciates the

excellent hygiene, speed and reliability provided by the gantry robot. |

(Sources from Cimcorp News 1/2001)